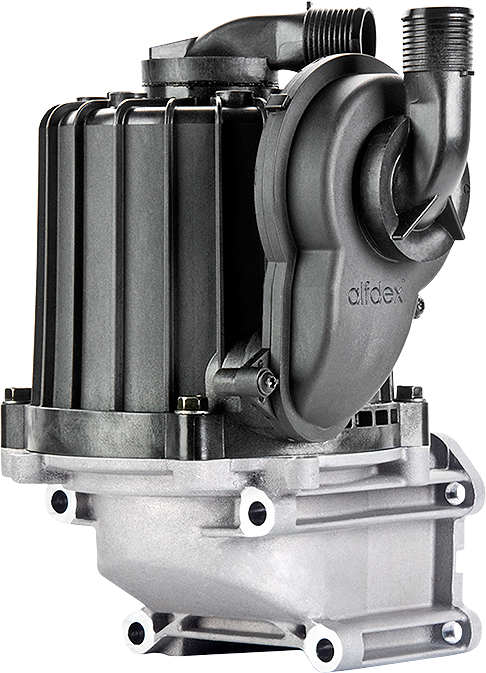

Superior technology for active

crankcase ventilation

The Alfdex g-Cleaner™ solves a major issue with combustion engines, especially when it comes to heavy-duty vehicles: crankcase gas. If the problem with crankcase gas isn’t addressed, crankcase gas will lead to decreased engine performance and oil leakage that will damage the environment. Due to this, many countries all over the world already have or are about to implement more stringent regulation into place.

The issue with crankcase gas

When unburned fuel or combustion gases leak from the combustion chamber past the piston rings (“blow by them”), they end up inside the crankcase. Although the amount of crankcase gas is limited in terms of volume, over time it causes pressure to build up in the crankcase. The gases can condense and get mixed in with the oil vapor, subsequently forming sludge, or causing the oil to degrade.

In addition, oil will leak, slowly but surely. A truck engine with 500 brake horse power creates around 10 cubic meters of blow-by gas per hour, containing 5-10 grams of oil. In a year this corresponds to around 30,000 m3 of blow-by gas and an annual loss of as much as 25 liters of oil from a typical truck engine. This is bad both for the environment and engine performance.

Crankcase ventilation systems

The simple solution is that the crankcase must be ventilated. A crankcase ventilation system (CVS) allows for the blow-by gases to escape from the crankcase without causing the damage described above. There are three types of systems, including closed CVS, where the gas enters the air inlet manifold, open CVS, where it’s vented into the atmosphere or filtered open CVS, where a filter is used. Both systems require a highly efficient solution for cleaning in order to meet the legislation.

With an Alfdex g-Cleaner™ for active crankcase ventilation you can enjoy cost savings while meeting environmental regulations.