Bad for the environment, bad for engine performance

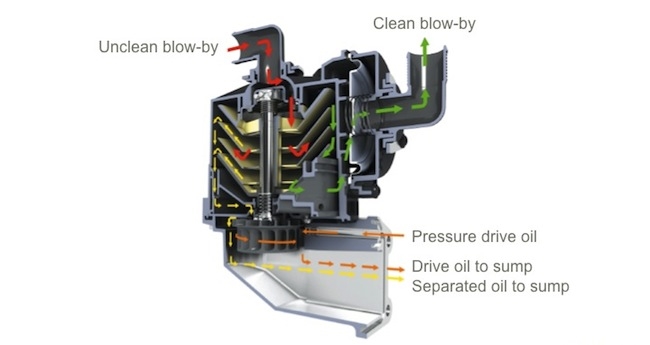

Crankcase gas originates from leakages that occur between the piston rings and the cylinder walls of an engine. The gas leaks down into the crankcase, where it generates a fine mist of oil droplets from the oil used for lubricating and cooling the engine. In order to prevent the pressure in the crankcase constantly increasing, the crankcase gas needs to be vented off.

Traditional solutions

The most common solution to this problem has been to make what is essentially a simple hole in the crankcase. The gas is then led through a pipe below the engine and out. Because this inevitably means greater oil consumption, it is not the best solution for either the environment or the engine performance. Oil traps are therefore commonly used to prevent the emission of too much lubrication oil. Nevertheless, this still results in an annual loss of as much as 25 litres of oil from a typical truck engine.

To avoid the oil wastage, some engine manufacturers have led the gas back into the engine’s air intake. This solution causes other problems. The blow-by gas contains oil and grime particles that can deposit on different components in the engine, thereby reducing the efficiency. Oil particles can burn and reduce the performance of the engine.

Our solution

There is a better solution that is also by far more future-proof than traditional methods. Experts at Alfa Laval, Haldex, and later Concentric, have all contributed to the successful technology found in the Alfdex® Oil Mist Separator. Their aim has always been to provide better fuel economy and reduced emissions while furthering productivity in vehicles, both on and off road, and they have succeeded with this solution. It can truly benefit your application through a number of benefits that you can read more about here.